PROCESS OPTIMIZATION

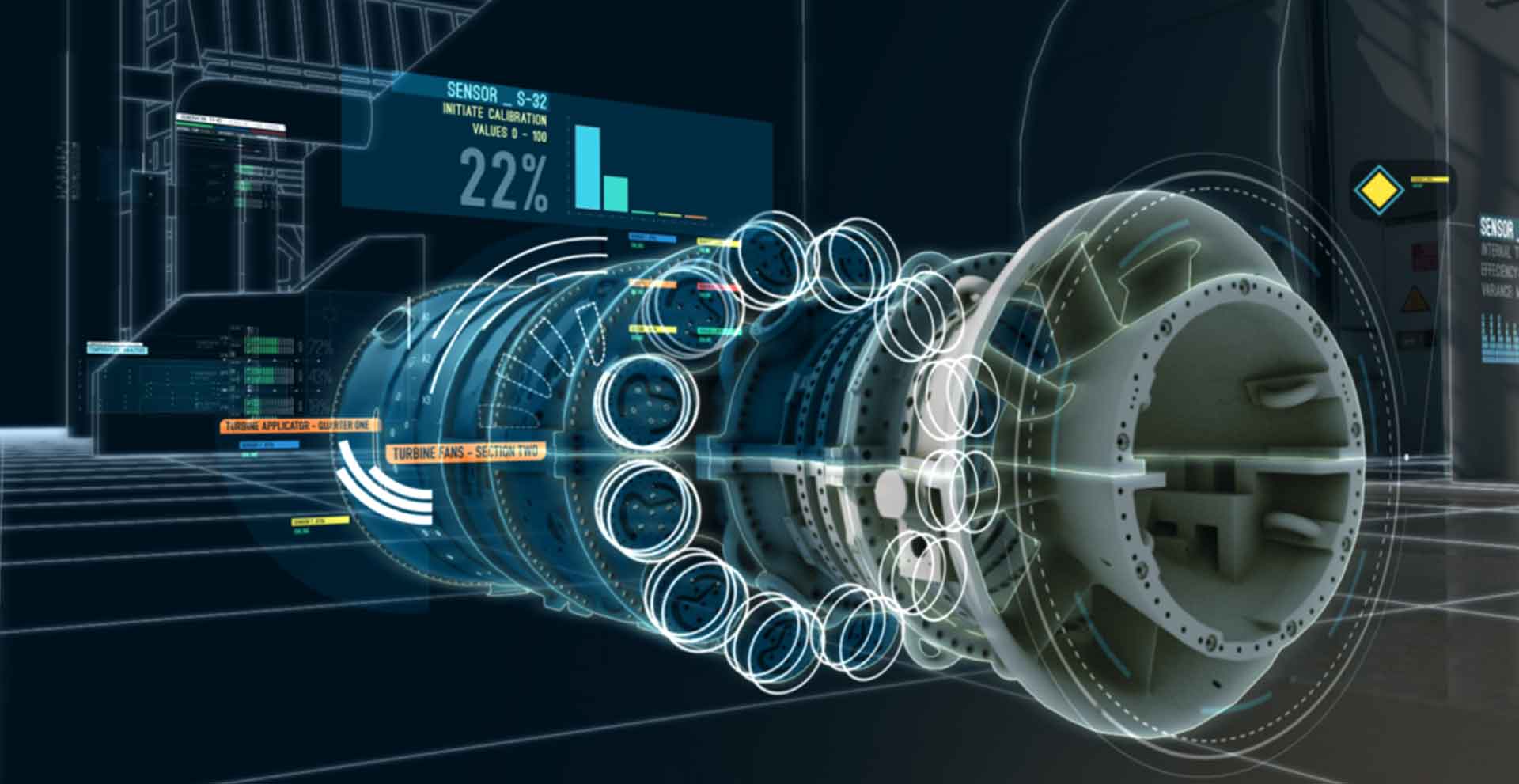

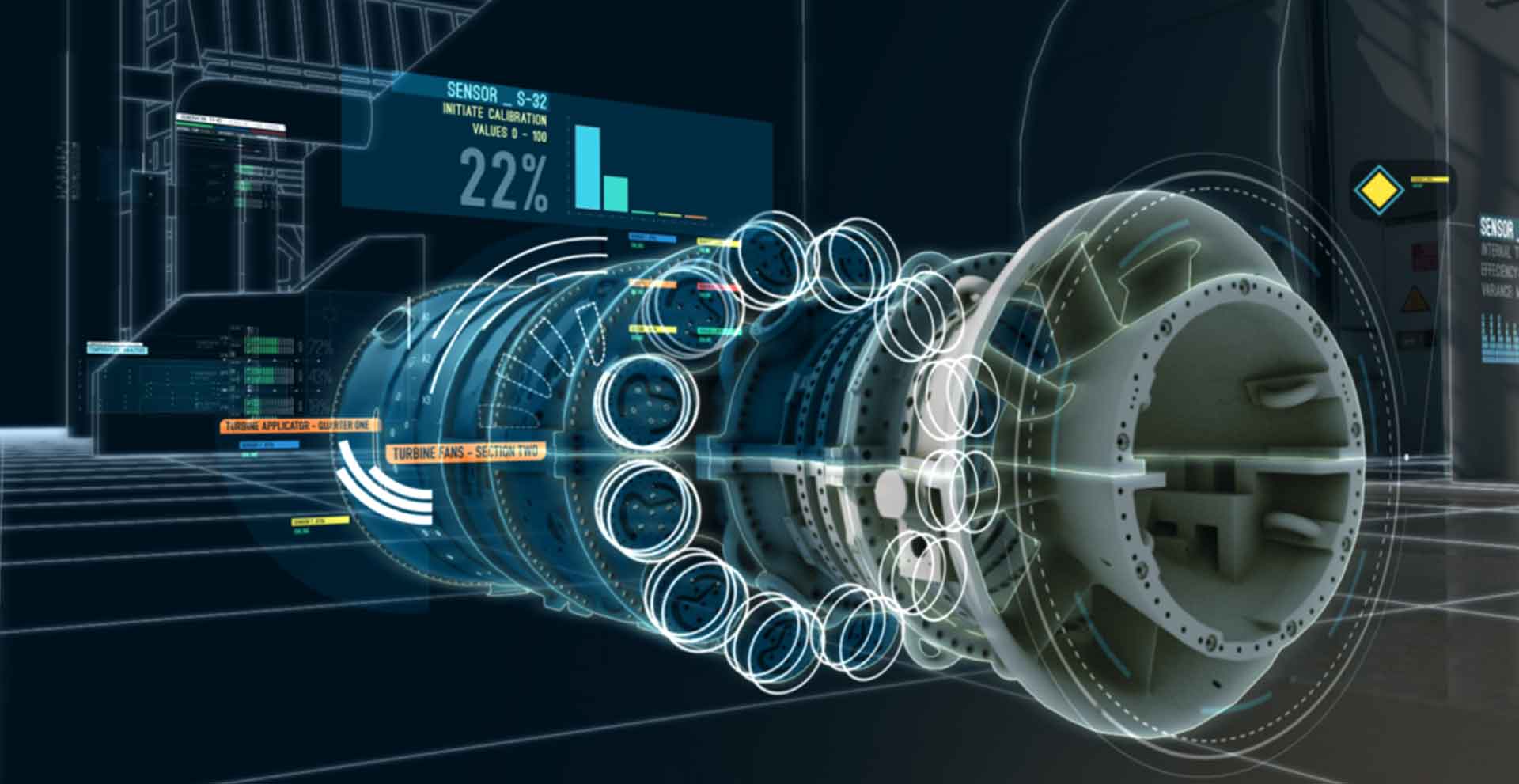

In complex industries such as Thermal Power, Oil and Gas, Chemicals, etc, assets are working round the clock with each other to achieve a combined goal. They operate in extreme and varying conditions (like input change, weather, demand change) which cause sub-optimalities. Digital Twin of an entire process helps model the relationships between multiple assets and learn the optimal configuration for any desired output. This helps plant personnel to operate assets and processes at the peak possible performance, always!

What is the Value?

Reduce wastage of resources

Improve Product Quality

Increase Production

Features

Data Sources

Optimization functions

Process Digital Twin

Live Predictions and Control Strategy

Data Sources

Live data from control & monitoring solutions, historians, asset design information and historic maintenance records.

Optimization functions

Build optimization models for your business priority using historic data – this can be to improve quality, reduce fuel or maximize output.

Process Digital Twin

Map the entire process and asset relationships back to a digital twin to get a full lifecycle context of the process and not merely individual data points.

Live Predictions and Control Strategy

Given a desired business outcome, improve the accuracy of existing process parameters in live operations to achieve optimization.